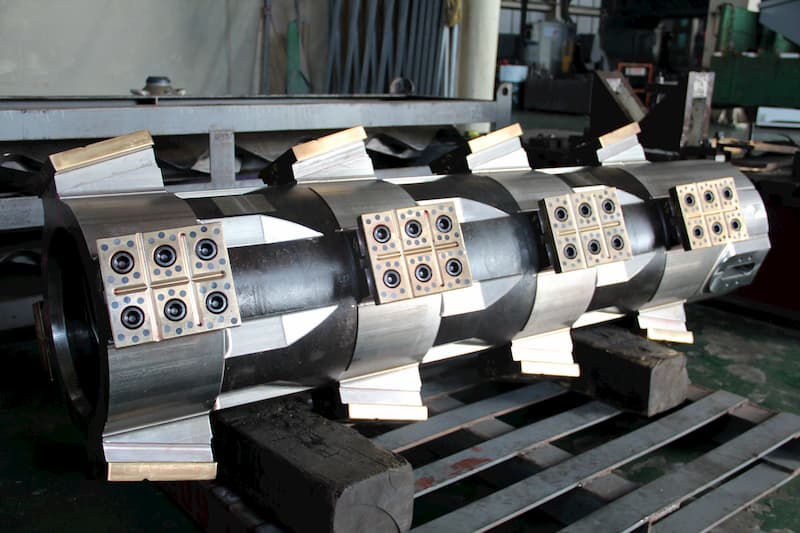

Reel/ spreader

The reel can be roughly divided into three parts:

(1) Mandrel,

(2)Segment,

(3)Other spare parts(slider, hydraulic cylinder, sun nut…etc.),whether it is for steel-coil producing or any other relevant processing of unrolled steel-coil, the reel will be a necessary equipment for the related manufacturing procedures.

Our advantages

砲管

砲管

We are experienced in making reels for years.In addition to Taiwan's market, we have also expanded our business to oversea markets. We currently have successfully developed markets in Vienam,China,and the United States. Morever,we have worked closely with China Steel, Taiwan's biggest steel company. With up-to-date knowledge ,cutting-edge techniques, and proper materials and selecting reliable suppliers, we make the production of our reel more proficient. And that's why 90% of China Steel's domestic reels are made by our company.

In order to meet the requirements of International standard of reel,we successfully produced the reel with nitriding-treatment on its surface in 2010. Comparing with high-frequency hardening or other surface heat treatments, it requires more prominent skills and productions due to more strict tolerance rate of deformation. It also shows how excellent products we can make by the hardness and smoothness of the reel surface. We proudly expanded our business to oversea markets by this outstanding capability.

Besides,we participated in the reel-spare-parts-refurbishment project from China Steel,Vienam Branch company in 2019. With our proficient skills,the batch of spare parts were successfully refurbished, and the service life of the reels has been greatly extended which largely saved the cost of purchasing new replacements and also assist our client to reduce the cost.

《 Contact us》for more information

Manufacturing procedures of Reel

Production lead time is around 195-240 days.